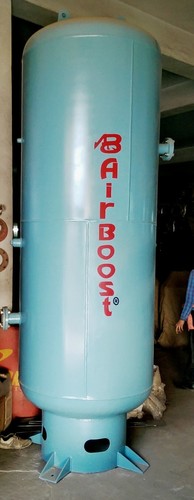

Industrial Air Receiver

Industrial Air Receiver Specification

- Air Pressure

- 8 bar

- Working Presssure

- 8 kg/cm

- Design Pressure

- 10 kg/cm

- Tank Material

- Mild Steel

- Volume of Tank

- 500 Liters

- Color

- Blue

- Dimension (L*W*H)

- 600 x 600 x 2000 mm

- Inner Diameter

- 600 mm

- Design Temperature

- 100C

- Height

- 2000 mm

- Air Outlet

- 1 inch BSP

- Capacity

- 500 L

- Working Temperature

- 80C

- Air Inlet

- 1 inch BSP

- Standard

- IS 2825 Certified

- Corrosion Protection

- Internal & External Coating

- End Type

- Dish Ends

- Usage

- Compressed Air Storage

- Mounting

- Leg Mounted

- Test Pressure

- 15 kg/cm²

- Finish

- Epoxy Coated

- Orientation

- Vertical

About Industrial Air Receiver

Industrial Air Receiver

We are manufacturing Air receivers as per IS 2825, IS 7938 and ASME Section VIII. Our qualified welders ensure to give the best quality air receivers upto a pressure range of 50 bar and capacity upto 2m3.. Our Air receivers are extensively used across the country in cement and power industry.

Superior Corrosion Protection

This air receiver tank utilizes advanced internal and external epoxy coatings, delivering comprehensive corrosion resistance for extended service life. Whether exposed to moisture or rigorous industrial environments, its protective measures greatly minimize maintenance requirements and ensure consistent operation throughout demanding workflows.

Certified Safety & Reliability

Engineered and manufactured according to IS 2825 standards, this air receiver offers reliable performance under pressure. With tested pressure ratings of up to 15 kg/cm, users can operate confidently knowing the system has been scrutinized for safety and durability. The robust mild steel construction and reinforced dish ends guarantee resilient structural stability.

Efficient Compressed Air Management

Designed for safe and efficient compressed air storage, the 500-liter vertical tank is essential in balancing fluctuations and streamlining supply in industrial pneumatic systems. Leg mounting facilitates convenient installation, while 1-inch BSP connections ensure versatile integration with standard air network configurations.

FAQs of Industrial Air Receiver:

Q: How is the Industrial Air Receiver installed in a facility?

A: The air receiver is conveniently leg-mounted, allowing stable positioning on flat surfaces. Its vertical orientation and compact footprint (600 x 600 mm base) make it suitable for spaces with restricted floor area.Q: What type of maintenance is required for the epoxy-coated air receiver tank?

A: Routine inspections are recommended to monitor the coating integrity, but thanks to comprehensive internal and external epoxy protection, the tank requires minimal maintenance and resists corrosion even in humid conditions.Q: Where can this air receiver be used within industrial processes?

A: It is designed for use in compressed air storage applications across a diverse range of industries such as manufacturing, processing plants, and workshops, supporting pneumatic tools and equipment.Q: What benefits does the IS 2825 certified design offer to users?

A: IS 2825 certification assures users that the tank meets rigorous safety and quality standards, making it dependable for high-pressure air storage and enhancing overall operational safety.Q: When should the air receiver be tested for pressure?

A: Pressure testing should be conducted during initial installation and periodically thereafter, confirming the vessel operates safely up to its test pressure rating of 15 kg/cm.Q: What is the process for connecting the air receiver to an existing compressed air system?

A: The tank is equipped with 1-inch BSP air inlet and outlet fittings, simplifying integration into established piping or distribution networks using standard connectors.Q: How does the vertical orientation of the receiver enhance its usage?

A: The vertical design optimizes space utilization and promotes efficient air separation, helping minimize water accumulation and enhancing overall pneumatic system performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Receiver Category

Industrial Air Receiver Tanks

Tank Material : Other , Mild Steel (MS), Stainless Steel (SS304/SS316) optional

Working Temperature : 10C to 80C

Capacity : 500L, 1000L, 2000L, 3000L, 5000L, custom sizes

Air Inlet : 1 to 2 (BSP/NPT Threaded or Flanged)

Air Outlet : 1 to 2 (BSP/NPT Threaded or Flanged)

Height : Customizable (commonly from 1000 mm to 3000 mm)

Electric Metal Air Receivers

Tank Material : Other , Mild Steel

Working Temperature : 10C to +50C

Capacity : 500 liters

Air Inlet : 1 inch BSP

Air Outlet : 1 inch BSP

Height : 1800 mm

Customized Air Receiver

Tank Material : Other , Mild Steel

Working Temperature : 35C

Capacity : 500 Litres

Air Inlet : 1 BSP

Air Outlet : 1 BSP

Height : 1600 mm

Vertical Air Receiver

Tank Material : Other , Mild Steel (MS)

Working Temperature : 45C

Capacity : 0.5 m

Air Inlet : 1 inch BSP

Air Outlet : 1 inch BSP

Height : 2100 mm

GST : 06AADCD1215A1ZL

|

|

AIR BOOST (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry