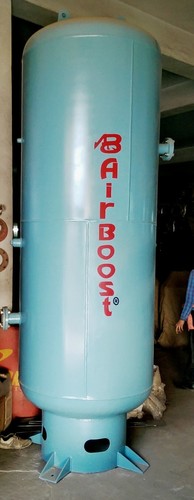

Air Receivers for air blaster

Air Receivers for air blaster Specification

- Color

- Blue (Industrial Epoxy Paint)

- Working Presssure

- 10 kg/cm

- Working Temperature

- Up to 65C

- Height

- 1500 mm

- Design Temperature

- 65C

- Dimension (L*W*H)

- 600 mm x 600 mm x 1500 mm

- Air Inlet

- 1 inch BSP

- Volume of Tank

- 400 Liters

- Tank Material

- Mild Steel (Seamless or Welded)

- Air Outlet

- 2 inch BSP

- Inner Diameter

- 600 mm

- Design Pressure

- 12 kg/cm

- Air Pressure

- 8 to 12 kg/cm

- Capacity

- 400 Liters

- Operating Medium

- Compressed Air

- Manhole/Access Port

- Provided For Cleaning & Inspection

- Shell Thickness

- 6 mm

- Application

- Used as Storage & Supply Vessel For Air Blaster Systems

- Mounting Type

- Vertical, With Sturdy Base Plate

- Number of Nozzles

- 2-3 Nozzles, Customizable

- Compliance Standard

- IS:2825 / ASME Sec VIII Div 1

- Safety Accessories

- Pressure Relief Valve, Drain Valve, Pressure Gauge

- External Surface Finish

- Anti-corrosive, Industrial Grade Epoxy Primer

- Hydro Test Pressure

- 15 kg/cm²

- Seam Type

- Fully Welded

- Corrosion Allowance

- 2 mm

About Air Receivers for air blaster

DR AIR BOOST high pressure air receiver stores peak demands of compressed air. The result is readily available air at a constant pressure. By avoiding undue load/unload cycles it saves energy costs and extends the life of the compressor.Robust Industrial Construction

Engineered for demanding environments, our air receivers feature fully welded seams, a shell thickness of 6 mm, and an extra 2 mm corrosion allowance. The anti-corrosive, industrial-grade epoxy primer guarantees maximum longevity, even in aggressive industrial settings. The sturdy vertical design includes a base plate for reliable installation and stability.

Efficient Operation & Safety

Designed for seamless integration into air blaster systems, the air receiver operates at up to 10 kg/cm, with a maximum hydro test pressure of 15 kg/cm. It is equipped with essential safety accessories such as pressure relief valves, drain valves, and a pressure gauge, ensuring safe and smooth operation in your facility.

Easy Maintenance & Customizable Options

A dedicated manhole/access port is provided for cleaning and inspection, making maintenance straightforward. With 2-3 customizable nozzles, varying inlet and outlet diameters, and options for dimensions and materials, these receivers can be tailored to meet specific storage or supply needs within your operations.

FAQs of Air Receivers for air blaster:

Q: How does the anti-corrosive epoxy primer benefit the air receiver in industrial applications?

A: The anti-corrosive, industrial-grade epoxy primer protects the external surface of the air receiver, significantly enhancing resistance to environmental factors such as moisture and chemicals. This robust finish extends the lifespan of the vessel and ensures reliable operation in harsh industrial settings.Q: What is the process for cleaning and inspecting the air receiver?

A: The air receiver is equipped with a manhole/access port that facilitates easy internal cleaning and inspection. Routine maintenance involves opening this port to inspect for wear or possible corrosion, cleaning the inner surfaces, and checking safety accessories like valves and gauges for functionality.Q: Where is this air receiver typically installed within an air blaster system?

A: The receiver is installed in a vertical orientation using its sturdy base plate, typically near the air blaster assembly. Its position enables it to efficiently store and release compressed air as required, while remaining accessible for monitoring, maintenance, or inspection.Q: What safety accessories are included with the air receiver?

A: The air receiver comes with essential safety accessories, including a pressure relief valve to prevent over-pressurization, a drain valve for releasing accumulated condensate, and a pressure gauge for ongoing pressure monitoring, ensuring safe operation within the specified limits.Q: Can the number of nozzles and dimensions of the air receiver be customized?

A: Yes, customization options are available for the number of nozzles (2-3), dimensions, inlet and outlet sizes, and tank specifications. This ensures seamless integration into varied system requirements and optimizes air storage and supply based on specific operational needs.Q: What are the main benefits of using this air receiver for air blaster systems?

A: This air receiver offers reliable compressed air storage, enhanced safety due to advanced accessories, and long-term durability from its corrosion-resistant construction. Its design supports easy maintenance and adaptability, making it an excellent choice for efficient air blaster system performance.Q: What standards does the air receiver comply with?

A: The air receiver is manufactured in adherence to IS:2825 and ASME Sec VIII Div 1 standards, ensuring high-quality construction, safety, and reliability for use in industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Air Receiver Category

Custom Air Receiver

Tank Material : Other , Mild Steel (MS), optional Stainless Steel (SS)

Color : Blue (custom options available)

Capacity : 500 Liters

Air Pressure : 10 kg/cm

Design Pressure : 12 kg/cm

Volume of Tank : 500 Liters

Customized Air Receiver

Tank Material : Other , Mild Steel

Color : Blue / Customized

Capacity : 500 Litres

Air Pressure : 8 Bar

Design Pressure : 10 Bar

Volume of Tank : 500 Litres

Electric Metal Air Receivers

Tank Material : Other , Mild Steel

Color : Blue

Capacity : 500 liters

Air Pressure : 10 bar

Design Pressure : 12 bar

Volume of Tank : 500 liters

Air Receiver Storage Tanks

Tank Material : Steel

Color : Grey

Capacity : 2m3 m3/hr

Air Pressure : 50 Bar

GST : 06AADCD1215A1ZL

Unit 1- 399, Sector-23, Faridabad - 121001, Haryana, India

Phone :07313726281

|

Unit 2- 368, Sector-24, Faridabad, Haryana - 121001

|

AIR BOOST (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry