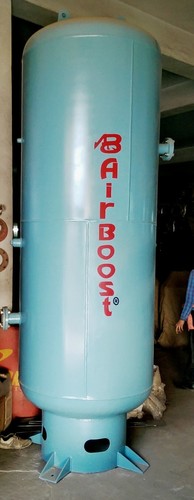

Custom Air Receiver

Custom Air Receiver Specification

- Dimension (L*W*H)

- 850 x 600 x 2050 mm

- Working Presssure

- 10 kg/cm

- Design Pressure

- 12 kg/cm

- Working Temperature

- Ambient to 60C

- Height

- Customized as per requirement

- Inner Diameter

- 600 mm

- Design Temperature

- 65C

- Air Outlet

- 1 inch BSP

- Volume of Tank

- 500 Liters

- Capacity

- 500 Liters

- Tank Material

- Mild Steel (MS), optional Stainless Steel (SS)

- Color

- Blue (custom options available)

- Air Pressure

- 10 kg/cm

- Air Inlet

- 1 inch BSP

- Hydrostatic Test

- Conducted at 1.3 times working pressure

- Test Pressure

- 15 kg/cm²

- End Connections

- Flanged/BSP/NPT (as per requirement)

- Drain Valve

- 1 inch automatic/manual

- Manhole

- Provided (optional depending on model)

- Operating Medium

- Compressed Air

- Mounting

- Vertical with sturdy base

- Corrosion Protection

- Internal shot-blasted with external polyurethane paint

About Custom Air Receiver

Air Receiver

We are manufacturing Air receivers as per IS 2825, IS 7938 and ASME Section VIII. Our qualified welders ensure to give the best quality air receivers upto a pressure range of 50 bar and capacity upto 2m3.. Our Air receivers are extensively used across the country in cement and power industry.

Advanced Corrosion Protection

The internal surfaces of each air receiver are thoroughly shot-blasted, while the exterior is finished with polyurethane paint. This dual protection system is essential for preventing rust and ensuring a longer operational lifespan, even in demanding environments.

Customizable to Your Requirements

From connection types (BSP, NPT, or flanged) to tank material (mild steel or stainless steel), our receivers can be tailored to suit specific operational needs. Optional features like the manhole and different mounting options enhance usability and accessibility for maintenance.

Rigorous Safety and Compliance

Our tanks are hydrostatically tested at 1.3 times the working pressure, surpassing industry safety standards. With a design temperature up to 65C and ambient working capabilities, they are dependable assets in various industrial settings, making them trusted by manufacturers and service providers alike.

FAQs of Custom Air Receiver:

Q: How is the corrosion protection of these air receivers achieved?

A: Each air receiver is internally shot-blasted and externally coated with polyurethane paint. This robust process equips the tank to resist corrosion, ensuring a longer lifespan and reliable air quality.Q: What are the customization options for air receiver tanks?

A: You can select tank material (mild steel or optional stainless steel), dimensions, mounting method, end connections (Flanged, BSP, or NPT), and even color. Additionally, the manhole is provided based on model requirements.Q: When should the drain valve be used, and what types are available?

A: The tank features a 1-inch automatic or manual drain valve to efficiently remove accumulated moisture. Regular use helps maintain the systems efficiency and protects against internal corrosion.Q: Where are these air receivers typically installed?

A: Primarily designed for industrial and commercial sites, these vertical tanks are mounted on sturdy bases and can be installed wherever compressed air storage is needed, ensuring efficient integration with your air system.Q: What is the process for testing the air receivers pressure integrity?

A: Each receiver undergoes a hydrostatic test at 1.3 times its working pressure (15 kg/cm) to verify its ability to safely withstand operational stresses, thus ensuring compliance with safety standards.Q: How does the air receiver benefit a compressed air system?

A: The tank stabilizes air pressure, stores compressed air for peak demand, and helps remove water and oil particulates. This results in smoother operation, reduced compressor cycling, and increased system efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Receiver Category

Electric Metal Air Receivers

Tank Material : Other , Mild Steel

Dimension (L*W*H) : 650 mm x 650 mm x 1800 mm

Working Presssure : 10 bar

Design Pressure : 12 bar

Working Temperature : 10C to +50C

Inner Diameter : 650 mm

Vertical Air Receiver

Tank Material : Other , Mild Steel (MS)

Dimension (L*W*H) : 550 mm (D) x 2100 mm (H)

Working Presssure : 10 kg/cm

Design Pressure : 12 kg/cm

Working Temperature : 45C

Inner Diameter : 550 mm

Electric Industrial Air Receiver

Tank Material : Other , Mild Steel

Dimension (L*W*H) : 700 mm x 700 mm x 1800 mm

Working Presssure : 10 kg/cm

Design Pressure : 10.5 kg/cm

Working Temperature : 45C

Inner Diameter : 610 mm

Industrial Air Receiver

Tank Material : Other , Mild Steel

Dimension (L*W*H) : 600 x 600 x 2000 mm

Working Presssure : 8 kg/cm

Design Pressure : 10 kg/cm

Working Temperature : 80C

Inner Diameter : 600 mm

GST : 06AADCD1215A1ZL

|

|

AIR BOOST (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry