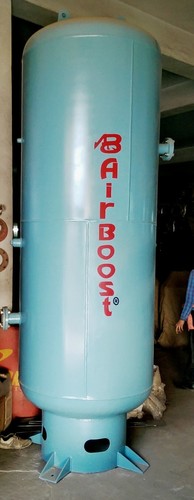

Electric Industrial Air Receiver

Electric Industrial Air Receiver Specification

- Dimension (L*W*H)

- 700 mm x 700 mm x 1800 mm

- Tank Material

- Mild Steel

- Inner Diameter

- 610 mm

- Color

- Blue

- Design Temperature

- 65C

- Design Pressure

- 10.5 kg/cm

- Working Temperature

- 45C

- Air Pressure

- 10 kg/cm

- Air Outlet

- 1 Inch BSP

- Capacity

- 500 Ltr

- Height

- 1800 mm

- Working Presssure

- 10 kg/cm

- Air Inlet

- 1 Inch BSP

- Volume of Tank

- 500 Liters

- Corrosion Resistance

- Yes

- Orientation

- Vertical

- Usage/Application

- Compressed Air Storage

- Mounting Type

- Floor Mounted

- Finish Type

- Powder Coated

- Testing Pressure

- 15 kg/cm²

- Drain Valve

- Yes

- No. of Legs

- 4

- Manhole

- Provided

About Electric Industrial Air Receiver

Air Receiver

We are manufacturing Air receivers as per IS 2825, IS 7938 and ASME Section VIII. Our qualified welders ensure to give the best quality air receivers upto a pressure range of 50 bar and capacity upto 2m3.. Our Air receivers are extensively used across the country in cement and power industry.

Superior Corrosion Protection

Powder-coated in blue and made from high-quality mild steel, this air receiver ensures outstanding resistance to rust, prolonging lifespan and reducing the need for frequent maintenance. It stands up to harsh industrial environments, making it a durable choice for demanding applications.

Optimal Storage and Safety

With a 500-liter capacity and vertical orientation, the receiver safely stores compressed air at design pressures up to 10.5 kg/cm. Safety is further enhanced with a sturdy, four-leg floor mount, a pressure-tested design, and essential features like a manhole and drain valve for easy access and drainage.

Versatile Application Across Industries

Engineered for use in various sectors, this receiver supports exporters, manufacturers, service providers, and suppliers throughout India. It ensures reliable air supply for tools, automation, and process functions, boosting productivity for diverse industrial operations.

FAQs of Electric Industrial Air Receiver:

Q: How is the Electric Industrial Air Receiver installed and mounted?

A: The receiver comes with a vertical floor-mounted design supported by four robust legs, ensuring stable placement on industrial floors. Installation requires positioning the tank securely, connecting the 1-inch BSP air inlet and outlet, and making sure all fittings are tightly sealed.Q: What is the purpose of the manhole and drain valve in this air receiver?

A: The provided manhole allows for easy internal inspection, cleaning, and maintenance, while the drain valve facilitates removal of accumulated moisture and condensate, ensuring the tank remains efficient and free from corrosion over time.Q: When should routine maintenance or inspection be performed?

A: Routine inspection and maintenance should be scheduled according to your operational workload but generally should occur at least once every three months. Regularly checking the tanks structural integrity, manhole, and drain valve helps preserve performance and safety.Q: Where can this air receiver be used effectively?

A: This air receiver is suitable for a wide range of industries, including manufacturing plants, workshops, and service facilities across India. Its corrosion-resistant build and efficient compressed air storage make it adaptable to both small and large-scale operations.Q: What is the working process of this air receiver in compressed air systems?

A: Compressed air from the main compressor enters the receiver through the 1-inch BSP inlet. The tank acts as a storage buffer, regulating airflow, minimizing pulsation, and allowing consistent supply at 10 kg/cm working pressure to downstream equipment via the outlet.Q: What are the benefits of the powder-coated, mild steel construction?

A: The powder-coated mild steel body offers excellent durability and resistance against rust and physical wear, ensuring longevity. This finish also enhances the receivers appearance and simplifies cleaning and maintenance procedures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Receiver Category

Air Receivers for air blaster

Air Outlet : 2 inch BSP

Air Pressure : 8 to 12 kg/cm

Capacity : 400 Liters

Height : 1500 mm

Working Presssure : 10 kg/cm

Volume of Tank : 400 Liters

Vertical Mild Steel Air Receiver

Air Outlet : 1 inch BSP

Air Pressure : 10 bar

Capacity : 500 Liters

Height : 2000 mm

Working Presssure : 10 bar

Volume of Tank : 500 Liters

Vertical Air Receiver

Air Outlet : 1 inch BSP

Air Pressure : 10 Bar

Capacity : 0.5 m

Height : 2100 mm

Working Presssure : 10 kg/cm

Volume of Tank : 500 Liters

Electric Metal Air Receivers

Air Outlet : 1 inch BSP

Air Pressure : 10 bar

Capacity : 500 liters

Height : 1800 mm

Working Presssure : 10 bar

Volume of Tank : 500 liters

GST : 06AADCD1215A1ZL

|

|

AIR BOOST (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry